Ironwood Electronics extended its high performance socket product line with smart features. Sockets are typically rated for 2K to 500K cycles. How do we know if the sockets are used for 100K or 200K insertions? Solution is electronic chip insertion counter. Our sockets can be integrated with electronics counter into the compression mechanism of the socket lid. A push button is exposed on the compression plate. Every time a chip is compressed, push button is actuated which in turn activates the electronic circuitry inside the lid. These activations are counted by the counter IC and displayed in LCD. Let’s say a contact element is rated for 2K insertions. After 2K insertions, this contact element will be replaced by new contact element. Now, the counter has to start the counting from the beginning. To achieve this function, a reset option is included in the electronics circuitry. When reset is actuated, LCD display will go to “0”.

Another feature of our smart socket is the temperature display. When the chip is operating at certain power, heat will be generated. If heat is not properly dissipated, the chip function will result in error. In order to properly dissipate heat, it has to be measured accurately. Solution is electronic temperature monitoring socket. Electronics is integrated into the top portion of the socket (either lid or compression knob) depending on space availability. A thermo couple sensor is brought down from the electronic circuitry to the internal socket cavity where the chip is placed. This thermocouple is spring loaded to achieve proper pressure on the chip surface. When the chip is placed and compressed against the PCB via contact element, the thermo couple touches top chip surface with enough pressure. Power supply is applied to the chip to start its function. As the chip start functioning, heat is generated. This heat is sensed by the thermo couple and fed to the electronic circuitry where it is processed and the temperature is displayed via LCD.

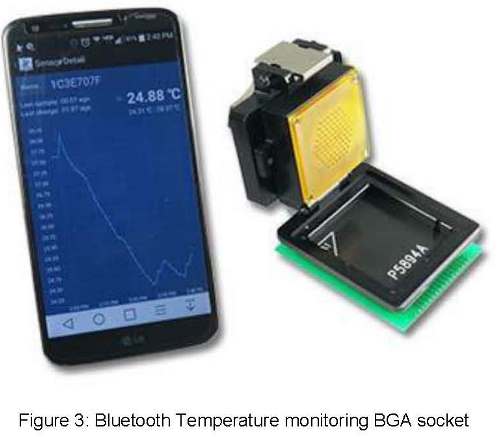

Another feature of our smart socket is the temperature display via bluetooth mobile app. BGA socket with Bluetooth electronic module integrated into the top portion of the socket (compression plate) is shown in the adjacent figure. This heat is sensed by the thermo couple in the compression plate and fed to the electronic circuitry where it is processed and the temperature is displayed via Bluetooth mobile app. The app monitors temperature continuously and provides results in graphical format. This feature is very useful in the test world during device characterization. Ironwood sockets can be integrated with either of these smart features. Custom features can be added to any our standard sockets and delivered in a quick turn time. |