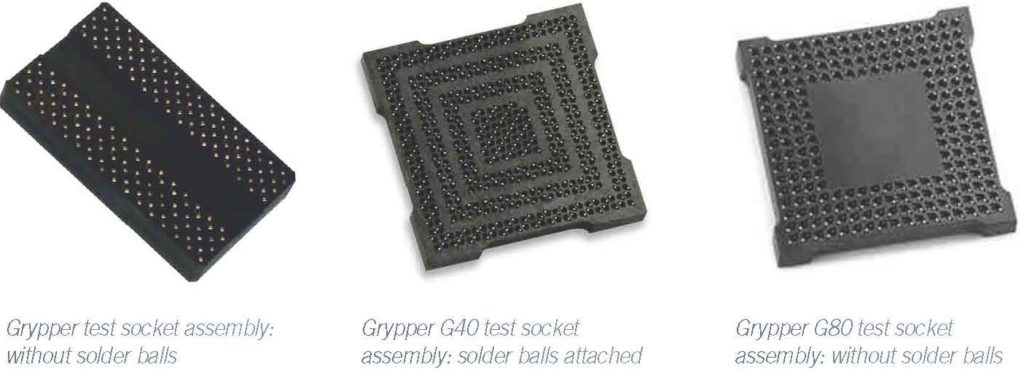

High-performance, 0.65 mm+ pitch net zero package footprint engineering test sockets for BGA style packaged devices over 200 ball count and for over 300 the G80 LIF to reduce insertion forces.

Technical Documents

- Grypper G80 Specification Sheet

- Grypper G80 LIF

- Grypper G80 0.45 Ball 0.8 Pitch RF Characterization Summary

- Grypper G80 0.50 Ball 0.8 and 1.0 Pitch RF Characterization Summary

- Grypper G80 0.60 Ball 1.0 Pitch RF Characterization Summary

- Grypper Attach & Removal Guide

- Grypper Insert & Removal

- Using Stencil Quik to attach Ironwood Grypper Sockets Guide

- Grypper Contact to Solder Ball Requirements

- Larger Grypper PCB Support

Grypper products test sockets consist of one standard part: the test socket assembly.

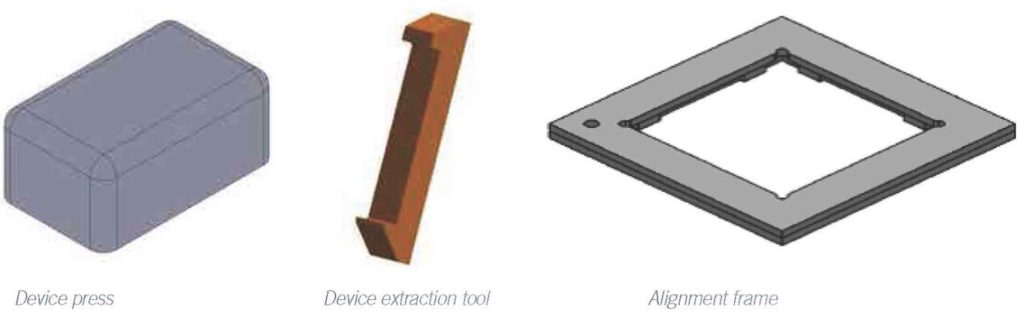

Additional components used with your test socket include the device press and the device extraction tool.

The Alignment frame is an option and is recommended for finer pitch (0.50 pitch and finer) and devices with solder balls of 0.40 diameter or smaller.

- Package-size PCB footprint: Since the PCB footprint of G80 is identical to the package, only one PCB design is required, enabling a seamless transition from test and validation through production and reducing overall test costs

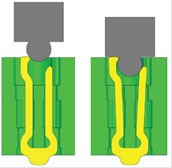

- Low insertion force: Unique contact design reduces the insertion force required to insert and retain higher-ball-count packages safely and securely within the test socket

- No lid required: The package snaps directly without a lid, enabling easy probing, scoping and troubleshooting the backside of the device

- Excellent signal performance: A short signal path achieves low inductance and low insertion loss, providing a nearly invisible electrical connection.