High Performance Near Zero Footprint Sockets for 0.40 + pitch devices. New Y contact is less aggressive to device solder ball allowing multiple insertions of the same deviceLower insertion – positive retention with spring bias Lid.

Technical Documents

- Grypper Y Specification Sheet

- Grypper Y RF Test Report

- Grypper Attach & Removal

- Grypper Insert & Removal

- DC Measurement Report

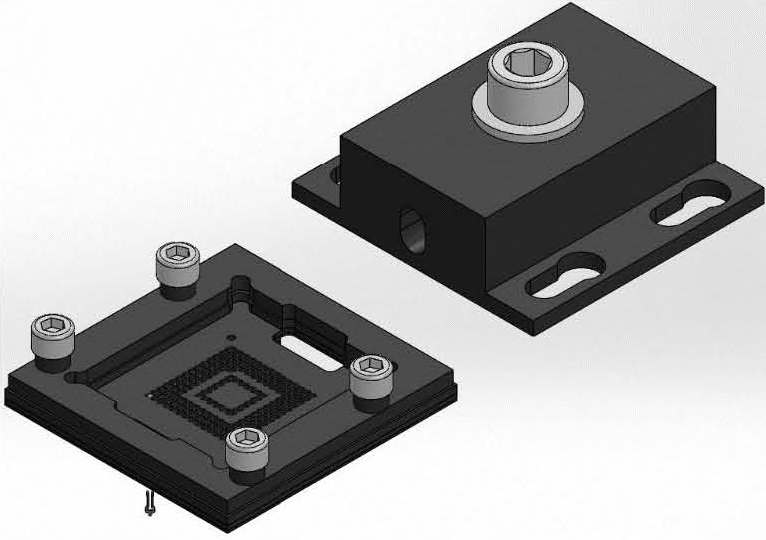

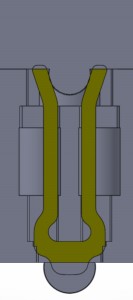

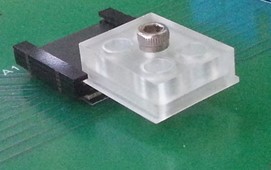

Ironwood Electronics new Grypper Y contact is design to work with BGA devices with solder balls/bumps with no equator or small exposure where the standard Grypper cannot reliable hold on to the solder ball. The Y shape, working with the sliding lid, allows reliable contact and ensures device retention in high vibration application. Lower forces, <25 grams, makes insertion easier too and the less aggressive contacting allows 40+ insertions of the same device. The Sliding Lid can be configured to include heat sinking. The Y contact designs cover BGA devices from 0.35 pitch and larger and the short electrical length has superior electrical performance.

Near Zero PCB footprint

The Grypper Y socket footprint is only 1 mm larger than the DUT. Typically this footprint will fit into any end application allowing the Grypper Y socket to be directly reflowed into the same location as the device.

Soft Contacting

The Y shape results in a wiping action and less aggressive contact to the solder ball which allows multiple insertions of the same device. The removal force is extremely low at ~3 grams / contact.

Sliding Lid

The Sliding Lid is used to insert the device and assures excellent contact. The screw on the top released the press onto the device so the forces are controlled and balance to each application. Different materials can be design in the lid to act as a heat sink.

Excellent Signal Performance

The Short signal path and two points of contact, achieves low CRES and low insertion loss.

|

|