High Performance, Industry Standard Zero Footprint Sockets for 0.35 + pitch devices.

Technical Documents

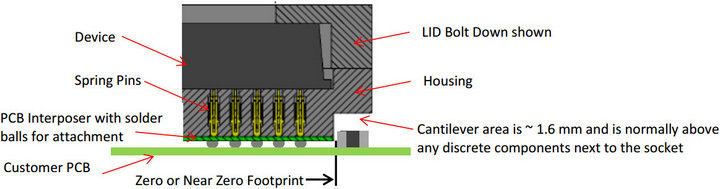

Ironwood Electronics Zero footprint (ZFP) sockets is a device size or near device size footprint test socket incorporating industry standard high performance spring pins. Ironwood can design a socket to work with any type IC packages; BGA- LGA – QFN- DFN and even leaded devices where you need to fit a socket in place of your device to allow fast, easy testing and development.

Features and Benefits:

Near Zero Footprint

The socket footprint is only 1 mm larger (0.5 mm per side) than the device for Near Zero Configurations. Typically this footprint will fit into any end application allowing the Spring Pin socket to be directly reflowed into the same location as the device. Depending on the ball configuration (BGA only) some designs can be made to a true Zero Foot Print.

Industry Standard Spring Pins

Ironwood Electronics has partnered with several Spring Pin manufactures so we can provide designs based on mechanical and electrical requirements, and cost points.

Lid Options

The Bolt Down Lid (standard) is a simple way to push the device into the socket. Optional Sliding Lid or ½ turn Lid is also available for higher insertion applications.

Excellent Signal Performance

Depending on the electrical performance needed, the ZFP SMT Spring Pin sockets can be designed using the best type pin required for your electrical requirements.