When an interconnection network is inserted within a transmission line between an IC device and the attaching PCB, the connectors used must provide superior electrical performance while also meeting a range of mechanical requirements.

Integrated circuits have transformed electronic device design. Integrated circuits, also called ICs or semiconductor devices, have enabled designers to continually increase device performance relative to both speed and functionality. This evolution in system design has been accompanied by new package styles that fit higher I/O counts into smaller spaces and reduce interconnect feature size. However, these factors place considerable demands on the sockets and adapters used for interconnection.

An IC connector is an electromechanical device that provides a pluggable interface between an IC package and a system circuit board or sub-assembly. This interface must exert a minimal effect on signal integrity and be replicated as needed. Connectors enable the interface to be easily removed, providing ease of assembly, upgradeability, maintainability, and cost savings. Sockets enhance ease of maintenance, testing, replacement, or upgrades.

Understanding the scattering and reflection properties of traveling waves when an interconnection network is inserted within a transmission line between an IC device and the attaching PCB becomes increasingly important as devices reach GHz-level operating frequencies and beyond. S-parameter measurements in terms of reflection coefficients and transmission gain have typically been accomplished via the use of network and signal analyzers coupled with the use of special test fixtures and probing devices. Based on these measurements, network analysis provides the appropriate S-parameters from which impedance values may be derived and directly correlated via the use of Smith Charts.

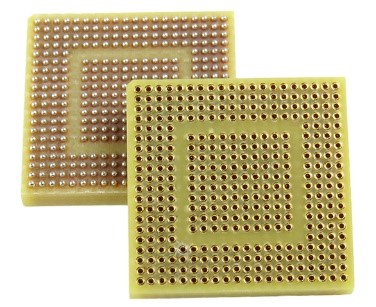

Figure 1: A custom 0.5mm pitch array connector by Ironwood Electronics.

For more info, please see .pdf below !!