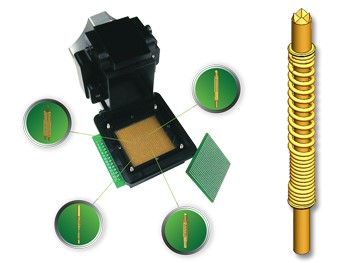

Ironwood Electronics’ new Spring Pin sockets (ESS) can be easily customized for specific test height, force, plating finish, materials, etc. The spring pin functions as the interface between the IC package and the circuit board. These contacts support up to 34GHz bandwidth with standard designs, and with customization, impedance can be matched for highest electrical performance. IC packages have various application requirements, which is why customization is critical to meet the specific IC test requirements.

|

Double-ended spring probes are primarily comprised of two plungers and spring. The spring (gold plated stainless steel or music wire) is sandwiched between two plungers (gold plated hardened Beryllium Copper). The spring has both open and offset closed coils, where both plungers interface within the closed coil area, enabling signals to pass straight through rather than inductively looping through the open coils. The spring probes have current ratings in the range of 1A to 4A based on geometry and material selection. The operating temperature range is -55°C to +150°C for stainless steel springs, and -55°C to +120°C for music wire springs.

Ease of customization provides many benefits, for example:

- Custom Force – Typical spring pins come in either 20g or 30g force, but a recent thermal cycling application required an optimum force of 26g – which was easily accomplished with our ESS pin.

- Custom Length – Many IC packages come with both balls and pads – requiring shorter spring pins for the balls and slightly longer ones to connect to the pads, while maintaining all other aspects of the same geometry.

- Custom Plating – IC packages with harder contact surfaces wear the gold plating of the spring pin tip. Custom plating, such as PdCo, accommodates hard surfaces.

- Custom Material – Contacts can be machined from custom alloys, such as Paliney.

- Kelvin Testing – Offset plungers for Kelvin applications.