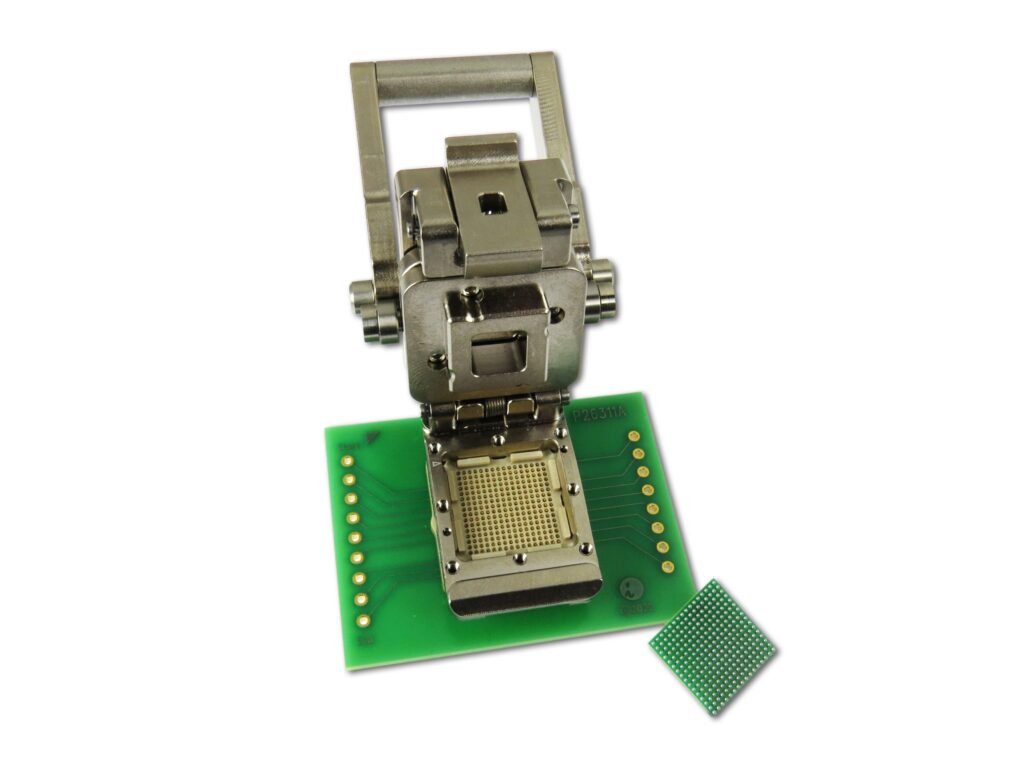

Socket and Test your 13x13mm BGA device using extreme temperature socket

Ironwood Electronics recently introduced a new Stamped spring pin socket addressing high performance requirements for testing BGA256 – CBT-BGA-6122. The contactor is a stamped spring pin with 31 gram actuation force per ball and cycle life of 125,000 insertions. The self inductance of the contactor is 0.88 nH, insertion loss < 1 dB at 15.7 GHz and capacitance 0.097pF. The current capacity of each contactor is 4 amps at 40 °C temperature rise. Socket temperature range is -55 °C to +180 °C. Socket features a clamshell lid design for ease of chip replacement in production environment along with precise ball to pin alignment via floating pin guide. It also has an integrated compression plate for vertical force actuation without distorting device position. The specific configuration of the package to be tested in the CBT-BGA-6122 is a BGA, 13x13mm, 0.8mm pitch 16×16 array with 256 balls. The socket is mounted using supplied hardware on the target PCB with no soldering, and uses the smallest footprint in the industry. The smallest footprint allows inductors, resistors and decoupling capacitors to be placed very close to the device for impedance tuning. To use, place BGA device into the socket and close the lid by snapping to the latch. Vertical force is applied by turning the lever that actuates cam which in turn compress spring loaded plate on to the BGA device. Socket features a central opening for thermocouple to be placed close to the device top surface or thermal stream to be flown to heat the device to specific temperature. This socket can be used for quick device screening, device characterization at extreme temperatures as well as final production test.