Ironwood Electronics is proud to offer a new line of standard footprint sockets that support high speed burn-in requirements using stamped spring pins, in machined metal housings rather than molded plastic. Continuously improved over the past 12 years, Ironwood has manufactured more than 50K units of our stamped spring pin sockets. The standardized design of the Aspen line enables reliable and repeatable socket function, while stocked components result in shorter lead times for quick design variations as well as lower cost due to economy of scale. The Aspen line accommodates device sizes ranging from 1mm to 60mm for any device type of 0.35mm pitch and above. BGA, LGA, QFN, CSP, and all types of leaded devices are supported.

The contactor is a stamped spring pin that has a rated cycle life of 50,000 to 125,000+ insertions and 14 to 31 gram actuation force per pin. The self-inductance of the contactor is 0.93 nH, insertion loss of < 1 dB up to 31GHz, and capacitance is 0.097pF. The current capacity of each contactor ranges from 2 to 8 amps. Socket temperature range is -55 °C to +180 °C. These unique contacts are designed with an outside spring and flat stamped plungers that provide a robust solution for Burn-in & Test applications, including excellent electrical signal integrity, to meet the requirements of today’s demanding analog, digital, RF, Bluetooth and medical device applications.

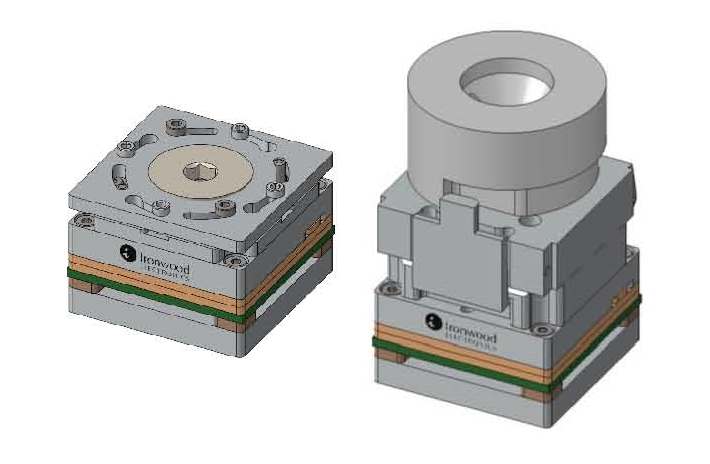

The socket is mounted using supplied hardware on the target PCB with no soldering, and uses a standard footprint allowing passive components to be placed very close to the device for impedance tuning. Simply drop IC into the socket and swivel the lid into place. Actuation force is applied by simply turning the compression screw. The compression plate, which is integrated with the lid, enables accurate and uniform force to be applied to the device, as well as quick and easy installation for rapid IC changes. These sockets can be used for device characterization, screening modules, and custom burn-in applications with the most stringent requirements.