Description

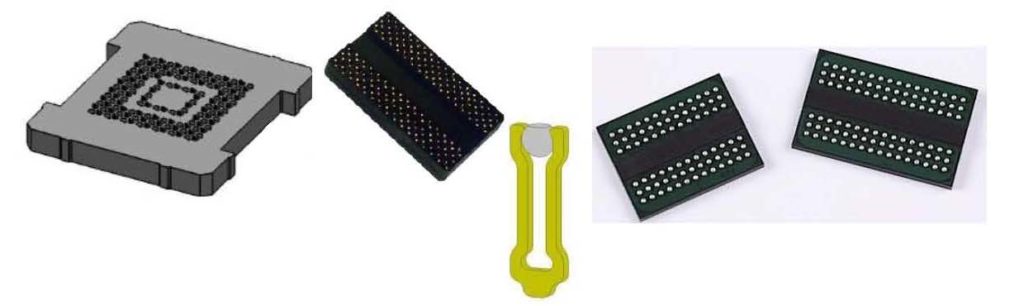

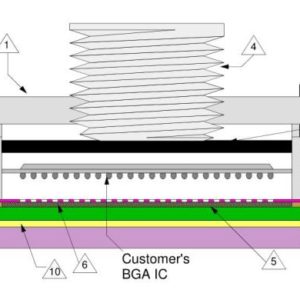

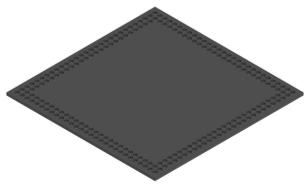

BGA Snaps into Socket – Zero Footprint – No Lid Required – S21 Electrical Performance >40 GHz (Grypper)

Device Solder Ball Requirements to fit Grypper Sockets

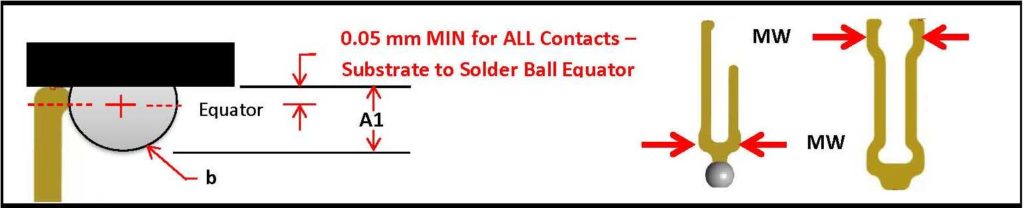

This document describes the minimum solder ball geometry typically required to work with the family of Ironwood Grypper style contacts.

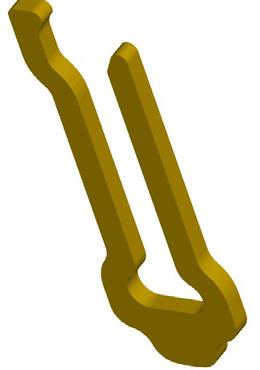

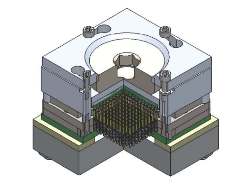

The Grypper technology relies on interfacing with the device solder ball that has a minimum exposure and a defined equator, such that the contact can wrap around the equator to ensure the “Grypping” action to the solder ball.

| Grypper Product | Solder Ball Diameter* Nominal +/-0.050 mm (b) | Typical* Min Ball Exposure (A1) =1/2b+0.05 | Min. Typ. Pitch (array) | Max. Contact Width (MW) | Min spacing diagonal ball to ball based on (MW) | Ironwood Contact P/N |

| G35 Grypper |

G35 Contact is used for Fine Pitch @ 0.35 mm |

|||||

| 0.20 | 0.130 | 0.35 | 0.355 | 104468-0028 | ||

|

G40 Grypper |

Standard G40 Grypper is used for 0.4 to 0.5 pitch devices |

|||||

|

|

0.25 | 0.175 | 0.40 | 0.425 | 104468-0014 | |

| 0.30 | 0.200 | 0.50 | 0.500 | 104468-0015 | ||

| 0.35 | 0.225 | 0.50 | 0.500 | 104468-0025 | ||

| 0.45 | 0.275 | 0.65 | 0.575 | 104468-0050 | ||

| Solder Ball Diameter* Nominal +/-0.050 mm (b) | Typical* Min Ball Exposure (A1) =1/2b+0.05 | Min Typical Pitch (array) | Maximum Contact Width (MW) | Min spacing diagonal ball to ball based on (MW) | Ironwood Contact P/N | ||

| G80 / G80 LIF Grypper | Standard Application | G80 LIF Applications |

LIF is used for Very High ball count devices- typically over 300 |

||||

|

|

0.40 | 0.35 | 0.225 | 0.65 | 0.640 | 104468-0053 | |

| 0.45 | 0.40 | 0.250 | 0.65 | 0.650 | 104468-0046 | ||

| 0.50 | 0.45 | 0.275 | 0.80 | 0.750 | 104468-0043 | ||

| 0.55 | 0.50 | 0.300 | 0.80 | 0.775 | 104468-0044 | ||

| 0.60 | 0.55 | 0.325 | 0.80 | 0.800 | 104468-0052 | ||

| 0.65 | 0.60 | 0.350 | 1.00 | 0.825 | 104468-0042 | ||

| Grypper | Standard Grypper is used for Ball Count up to 200 @ 0.65 – 1.0 pitch | ||||||

|

|

0.30 | 0.200 | 0.65 | 0.640 | 104799-0001 | ||

| 0.35 | 0.225 | 0.65 | 0.650 | 104799-0003 | |||

| 0.40 | 0.250 | 0.65 | 0.650 | 104799-0002 | |||

| 0.45 | 0.275 | 0.80 | 0.750 | 104468-0002 | |||

| 0.50 | 0.300 | 0.80 | 0.750 | 104468-0001 | |||

| 0.60 | 0.350 | 1.00 | 0.850 | 104653-0001 | |||

| 0.65 | 0.375 | 1.00 | 0.900 | 104653-0003 | |||

*Actual device solder ball measurements should be reviewed to ensure proper fit with socket contacts – A1 dimension calculated at nominal ball diameter, A1 can be less if the 0.05 MIN Substrate to Solder Ball Equator requirement is met.

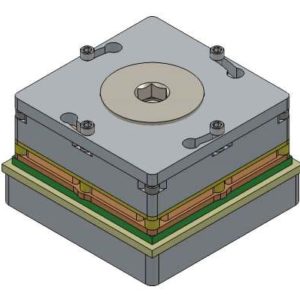

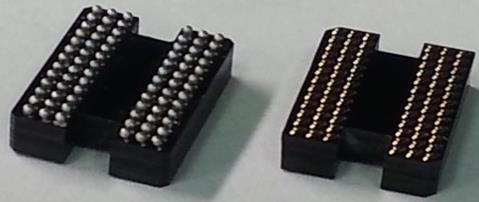

Standard Grypper and G80 Product do not have solder balls – stencil used for socket attachment – solder balling is an available option.

Stencil for Grypper and G80 socket attachment or G40 without solder balls:

Optional Solder balling on Grypper and G80:

G35 and G40 Typically are ordered WITH solder Balls but No solder ball option is also available – Stencils are not required with sockets with

solder balls. Socket attaches-reflows similar to a BGA device

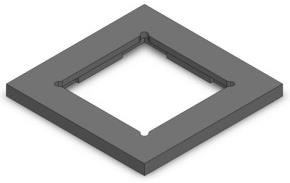

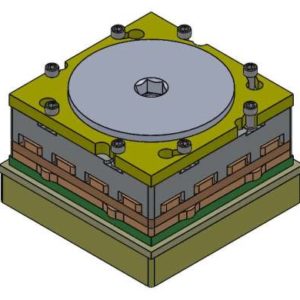

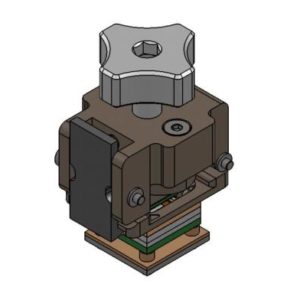

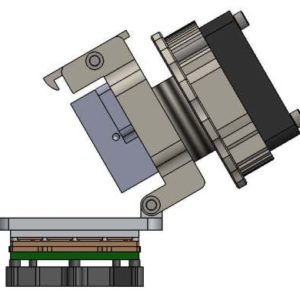

Alignment Frames are used with G35 / G40 product and recommended to ensure device alignment to socket, prior to insertion:

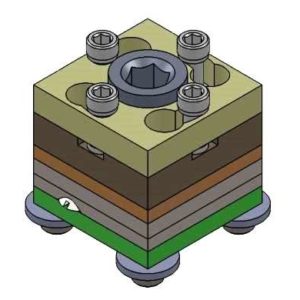

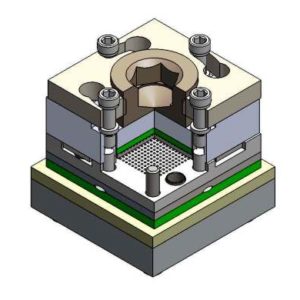

Optional Device Press to assist in uniform pressure across the top of the device for insertion:

© Copyright 2019 Ironwood Electronics / All rights reserved / Data subject to change without notice